Going Beyond

See what makes us different!

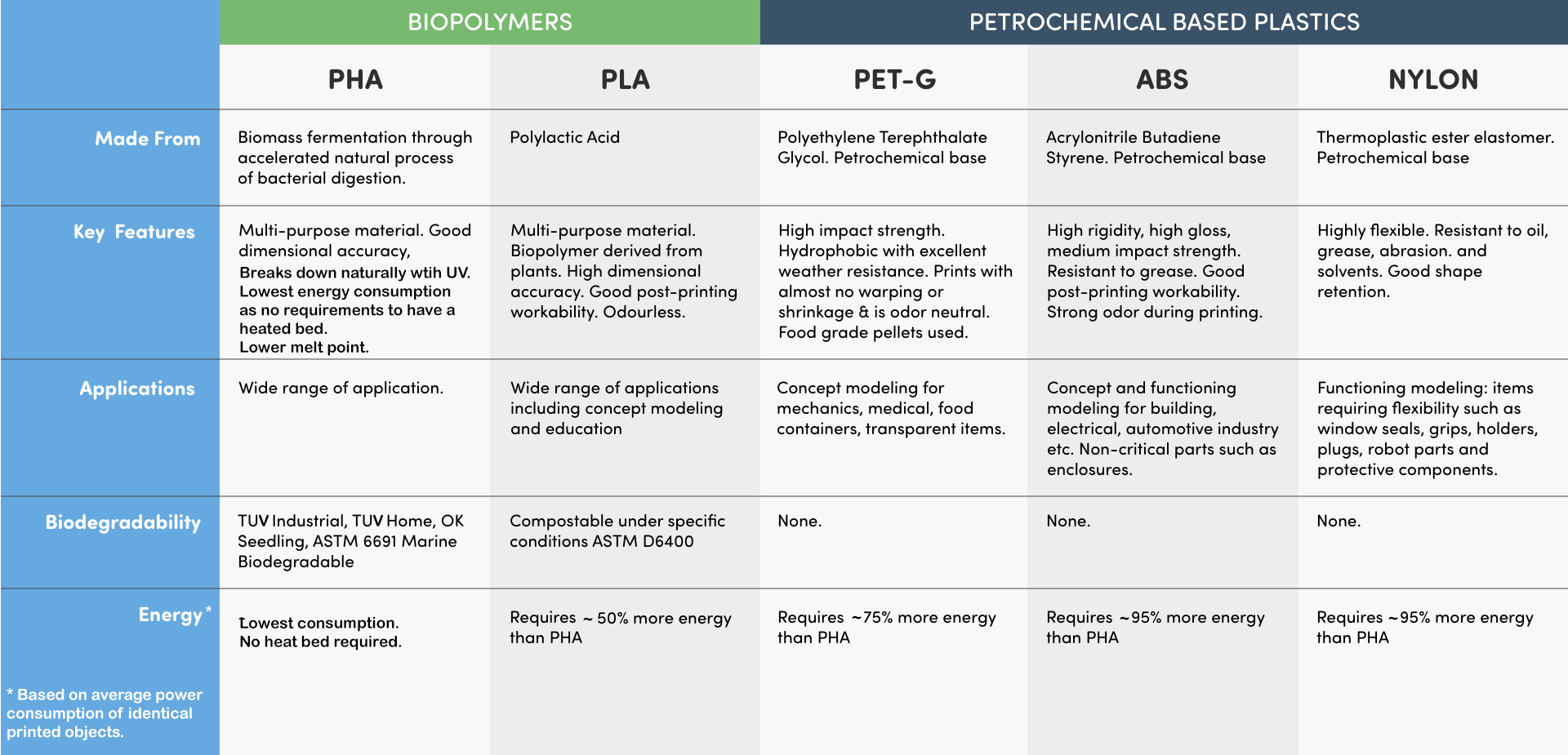

Bio-Plastics made from renewable sources are the future of the industry. PHA’s and PLA’s are a family of biopolymers used by those looking to make a sustainable change.

Other Petro-polymers or “Plastic Like” materials such as PET, HDPE, PS, ABS, PP and countless derivatives of the petrol base chemicals are thought to be “recyclable”, but the reality is that there are only two materials that are currently commercially viable to reprocess at scale, and they are PET and HDPE packaging. However, everything else labelled as “recyclable” is more than likely to end up in our landfills, or incinerators, and in the worst-case scenario, in our oceans where the long-term effects of these products become hazardous to our environment for generations.

PHA’s and PLA, while both being characterized as bio-polymers are very different in their manufacturing process and end of life. Both have been around commercially for over 30+ years, but they are significantly different in their end of life impacts. PHA is a polymer that is naturally synthesized in selected bacteria. For the past 30+ years, over 150 different naturally occurring bacteria have been found in nature to convert their favorite food into PHA. Some like sugars; some thrive on vegetable oil; others perform incredible work in our water and sewage treatment systems; and some love nothing more than to have their way with natural biogases such as methane and CO2.

The easiest method of discarding these components made of PHA is by allowing mother nature and its trillions of bacteria to re-digest their bio-polymer. This is called biodegradation. In addition, our materials are compostable, both in industrial and home composting systems. And as we grow the market and availability of these materials, their viability for recycling becomes tenable once there is enough volume to justify these resources.

This means our PHAs have three paths to their end of life.

Here's why...PHA End of Life

It has become clear that as consumers of “plastics”, we all must collectively think of not just the performance and/or appearance of the product, but also, its end of life. How will this component be discarded once it has completed its task or become unusable?

For our products, there are really 2 choices you can make every day.

Composting is currently the best option. If these municipal services are available, we encourage you to use these commercial composting services. Another option is home composting, if you happen to have home composting set up.

Recycling is the second choice. Recycling infrastructure will facilitate the collection of the material, which will be separated from the traditional recycled plastic. This material will then be discarded with the non-recyclable material, whose end of life is more than likely landfills. While that isn’t the optimum solution, our materials will go through their end of life within the landfill and will simply decompose in a similar fashion as cellulose products (paper and cardboards) and leave no hazardous contaminants behind.

The Biodegradability is the safety net, and it only comes into play if the product ends up being discarded within our biomes. Nature’s way of breaking down the material and not causing any short- or long-term negative impact is an amazing gift. However, we do not encourage anyone to think or believe this is a free license to litter or behave irresponsibly.

Briefly, PLA (Polylactic Acid) is a sugar based material that is fermented to produce Lactic Acid. This base material is then polymerized in reactors similar to Petro-chemicals using metal catalyst. The polymerization is artificially induced VS. the natural polymerization of PHA.

Therefore, PLA material is limited on its end-of-life options. Currently only in specific Industrial Composting conditions is PLA compostable. These are systems that will expose the PLA to a specific temperature and humidity range that is not achievable in-home composting. Unfortunately, if these materials end up in our biomes, they simply erode and breakdown into micro-plastic, which can build up contaminants in our environment.

There are advancements on this specific subject that are showing promising results. Meaning, improving the ability to decompose in more natural composting systems. These results still need further inspection and evaluation.

Plastic Comparison Chart